We believe that one of the primary obligations of every packaging manufacturer nowadays is environmental responsibility. At DOT2DOT, we feel responsible for our planet, which is why we continually strive to search for more sustainable technologies to make our packaging greener. Investing in sustainable development has become a key part of our corporate strategy.

ECOLURE Technology•

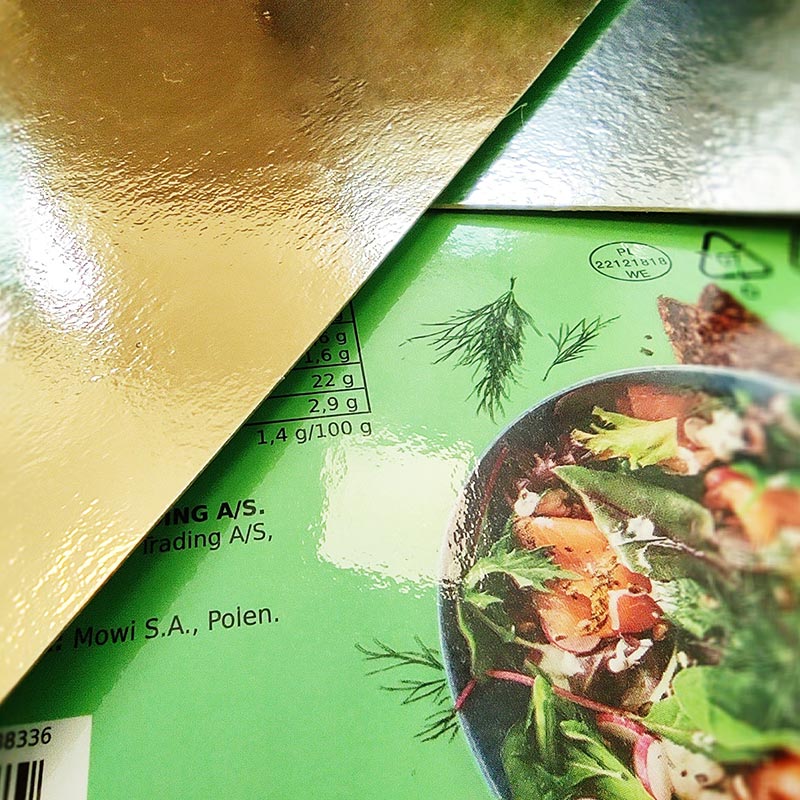

ECOLURE is our new eco-technology that offers the possibility to manufacture recyclable and compostable metallized packaging. It is a sustainable alternative to traditional PET lamination.

Eco-friendly packaging does not have to be grey and dull. Thanks to our recent development, it is now possible to have beautifully gleaming packaging radiant with colours completely free of PET foil, with excellent performance compared to the existing technologies.

Why is it easy to replace traditional laminate with ECOLURE?

ECOLURE is the outcome of a 2-year 11M euro research technology project, co-financed by the European Union from the funds of the European Regional Development Fund, in the framework of the Smart Growth Operational Programme 2014-2020. The Project is performed in the framework of the competition The National Centre for Research and Development: Fast Track

Program name

Smart Growth Operational Programme 2014-2020

Project name

Development of innovative and environmentally friendly cardboard packaging with optical protection on a metallized substrate

Beneficiary: Dot2Dot SA

Project Value: 50 406 079,80 zł

Value of EU Funding: 20 258 883,33 zł

Execution Period: 2020-2021

Project objective

The objective of the project was to develop innovative cardboard packaging on a metallised substrate with an optical protection option. As a result of the research and development work, the outcome products would ensure high biodegradability level of highly decorated packaging for FMCG and premium products markets.

Project assumptions

As part of research and development work DOT2DOT, as the beneficiary, would develop an innovaive product in the form of cardboard packaging on a metallised substrate and of the following properties

- High composability level combined with the highest quality visual effects

- Hight quality in the scope of endurance level

- High safety level of the packaging, enabling its usage for packaging food products

- Optical anti-counterfeiting protection

Project partners

The project is performed in cooperation with the Łukasiewicz Research Network, which is the third largest research network in Europe.

Dot2Dot assumes execution of the green orders. Purchases of the deliveries and services necessary for execution of the Project will be based upon selection of the most beneficial offers, from the economic point of view, but also taking into account the requirements concerning limitation of the negative influence on the environment. Moreover, in the framework of the conducted R + D works, the Company plans to work out an innovative product that will be manufactured in the framework of the process making use of the newest available solutions friendly for the environment (for example energy saving).

The Project is co-financed by the European Union from the funds of the European Regional Development Fund, in the framework of the Smart Growth Operational Programme 2014-2020. The Project is performed in the framework of the competition The National Centre for Research and Development: Fast Track.

Other eco-technologies we use

LED printing

This is a print technology that does not generate ozone, uses less energy during the production process and emits 8 times less heat than traditional UV technology.

Cold foil

This method of applying a layer of metal foil to achieve a shine effect is, in comparison to for instance hot stamping, more environmentally friendly, as it is eliminates an extra process and has lower heat emissions.

Plastic to Paper•

We help our customers implement solutions to replace plastic packaging with more sustainable alternatives with similar properties.

When we design windowed packaging, we use cellulose acetate film, which is fully biodegradable unlike traditional film.

We replace the substrate with a polyethylene barrier with a natural barrier of cardboard (without plastic) that has similar properties.

We develop cardboard packaging instead of a plastic-paper mix.

We have a wide range of environmentally friendly finishing options .

Other sustainable aspects of our work •

Sustainable procurement

Our basic raw materials used in production are paper and corrugated cardboard.

At DOT2DOT, we are committed to quality and safety at every step of the supply chain. We cooperate with the Forest Stewardship Council® (FSC®) and Programme for the Endorsement of Forest Certification (PEFC) certified suppliers on the basis of a mutually signed Code of Conduct. These certifications are the most important international programmes in the wood processing industry. They confirm that the wood used to produce the paper comes from responsibly managed sources and the paper production process complies with current EU legislation.

CO2 emissions

We implement active climate change prevention measures aimed at reducing greenhouse gas emissions in all DOT2DOT production sites. We monitor sources of emission in all our facilities. The calculation methodology that we use complies with the requirements of the GHG Protocol standard in accordance with ISO 14064-3.

We constantly strive to add positive value to the entire production chain, allocating more resources for climate-neutral transformations (energy, cooling technology, fleet management projects), and also by involving our suppliers in pro-ecological activities (cooperation with suppliers committed to responsible forest management, signing the Code of Conduct).

Zero waste

Zero waste is the approach that involves creating a closed-loop economy that reuses resources instead of creating waste. This means responsible production, consumption, reusing and recovering all products, packaging and materials posing environmental or health hazards without burning them, and without discharging them into the ground, water or air.

By definition of the Zero Waste International Alliance (ZWIA), zero waste is defined by following 5 key points:

- Refuse

- Reduce

- Reuse

- Recycle

- Rot (compost)

At DOT2DOT, we don’t just offer our customers products that are recyclable or biodegradable or made from raw materials that have been reprocessed. Under the integrated management system in place and as part of the production optimisation, we undertake a number of measures aimed at supporting zero waste operations. We recommend using eco-friendly inks in the production process. Post-production waste paper is reused. We also make efforts to optimise energy consumption by using energy-efficient lighting, encouraging our employees to save electricity in their daily work.

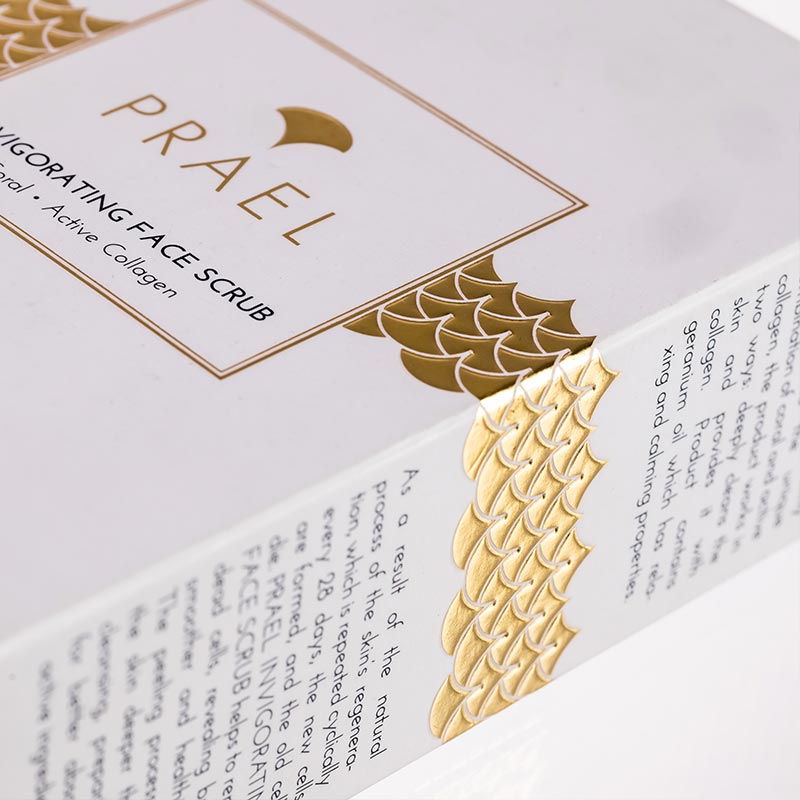

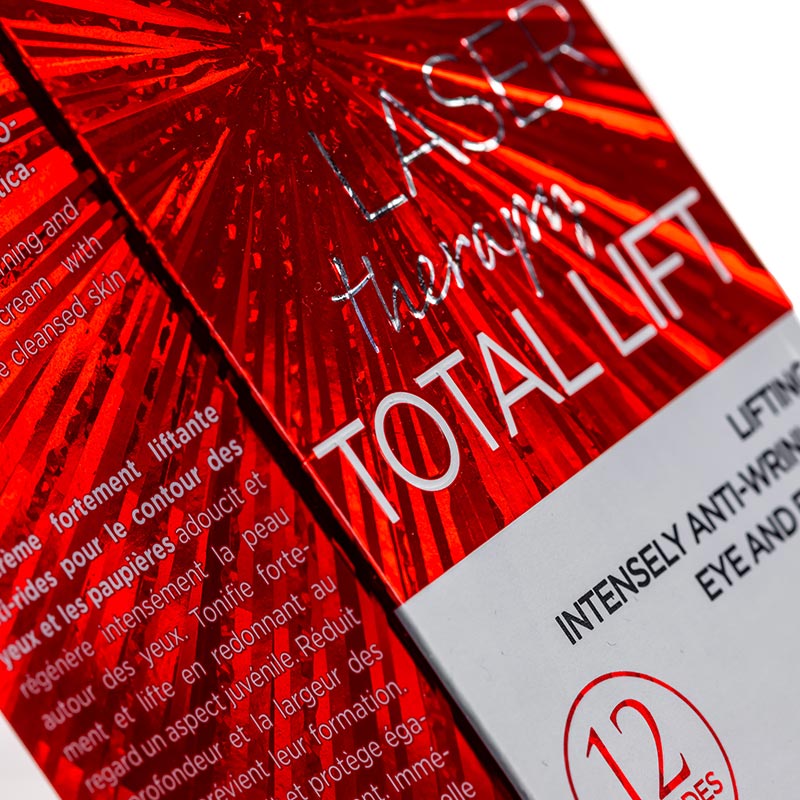

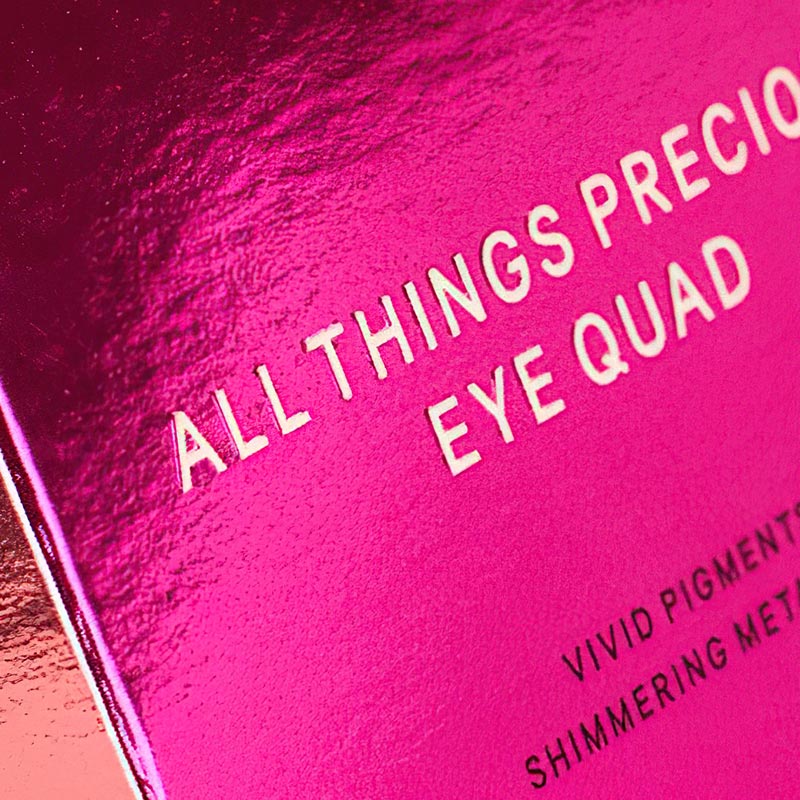

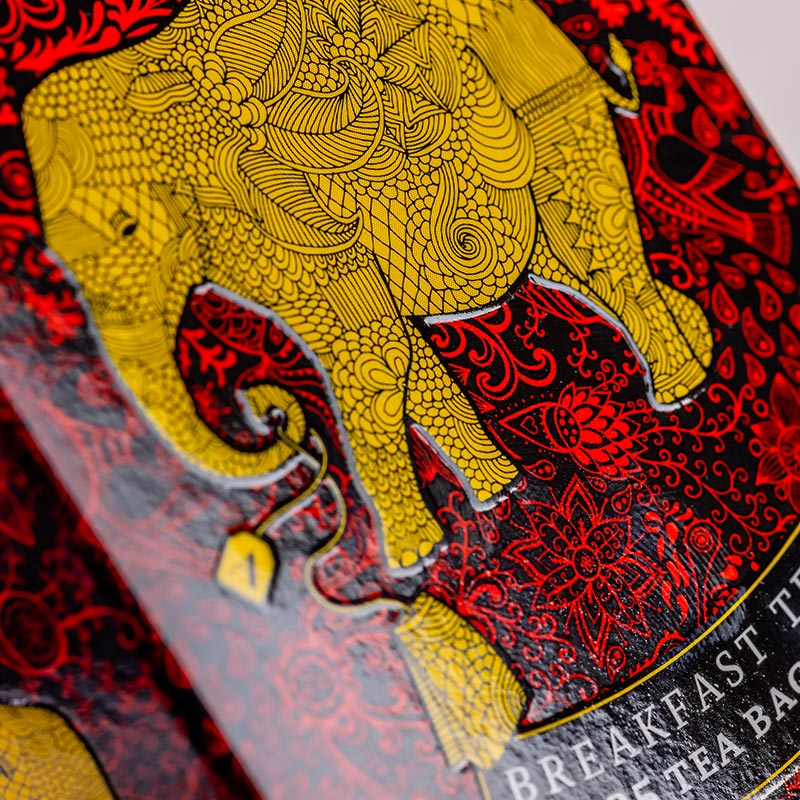

Cold foil•

Cold foil, or cold stamping, is a method of transferring a metallic layer onto the cardboard in the so-called “cold” foil printing process.

Processes involved:

- Application of an adhesive layer in the area where the foil will be transferred

- Application of an adhesive-coated metallised layer onto the substrate

- Surface printing using different drying technologies

Cold foil is used particularly in industries where the visual appeal of the packaging and intricate decoration is very important, mainly in the confectionery and cosmetics markets.

Our state-of-the-art machinery allows us to make full use of this technology to create appealing shiny effects on the packaging surface.

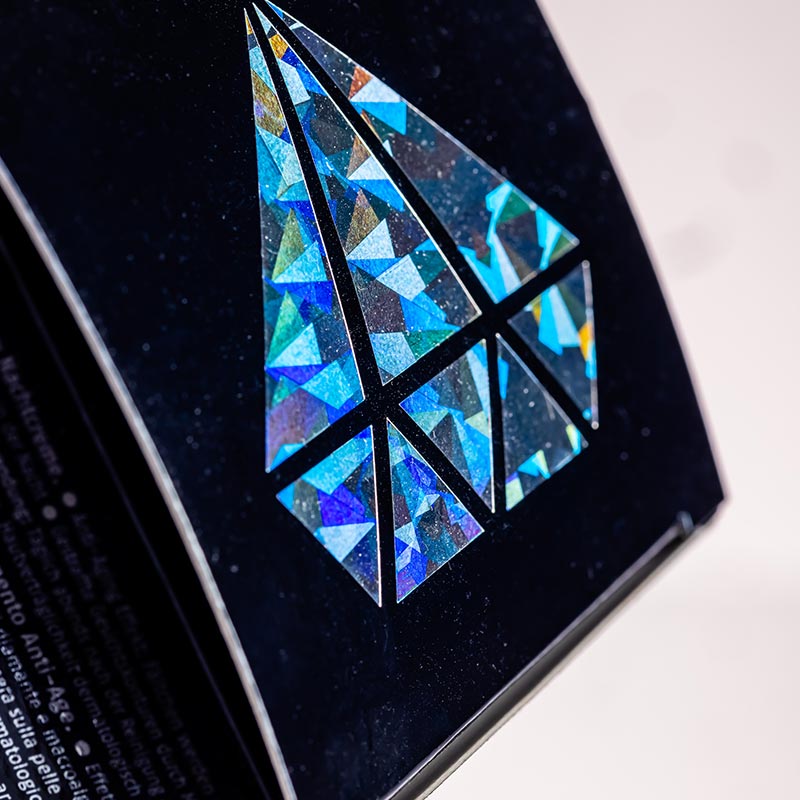

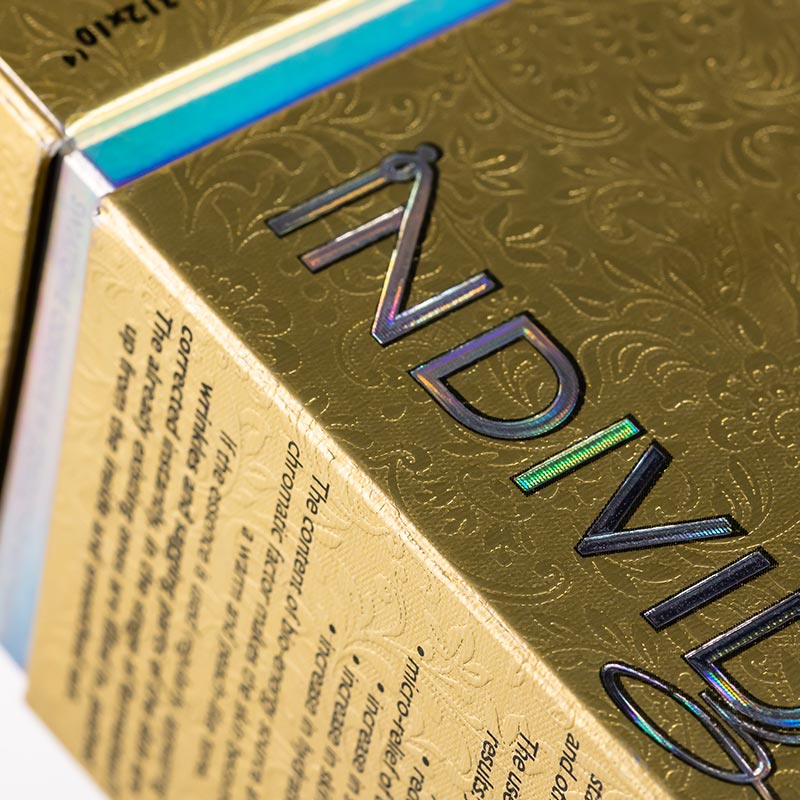

Hot stamping•

Hot stamping is a surface decoration method using high temperatures that results in a shiny metallic effect.

The process involves transferring a layer of aluminium from a carrier foil to the substrate. The aluminium layer is transferred by heating the dye to approximately 100°C which is the carrier of the pattern which is transferred onto the substrate.

- Contact between heated dye and foil

- Activation of the adhesive layer in the contact area

- Transfer of the aluminium layer by pressure and temperature

- The dye image reproduced remains on the substrate

The most common application of hot stamping can be found in the production of premium cardboard packaging where a large number of fine glossy elements need to stand out. Hot stamping is a perfect solution if you want to highlight small decorative details on the packaging, such as fragments of the logo, inscriptions, shapes (e.g. Christmas stars), as well as text. This technology is also used to secure products (holograms and holographic films). Hot stamping foils can be overprinted and varnished on top.

Lamination•

Conventional laminating (in the “cold” or “hot” process) is a technology in which the entire surface of a sheet is covered with a layer of PET film to create an attractive metallic coating. The substrate for lamination can be printed or unprinted, depending on the type of product and the desired effect, e.g. laminated trays for food or premium packaging.

At DOT2DOT, we have created an innovative new ECOLURE technology, allowing us to leave a shiny metallic layer on substrates by eliminating the PET film.

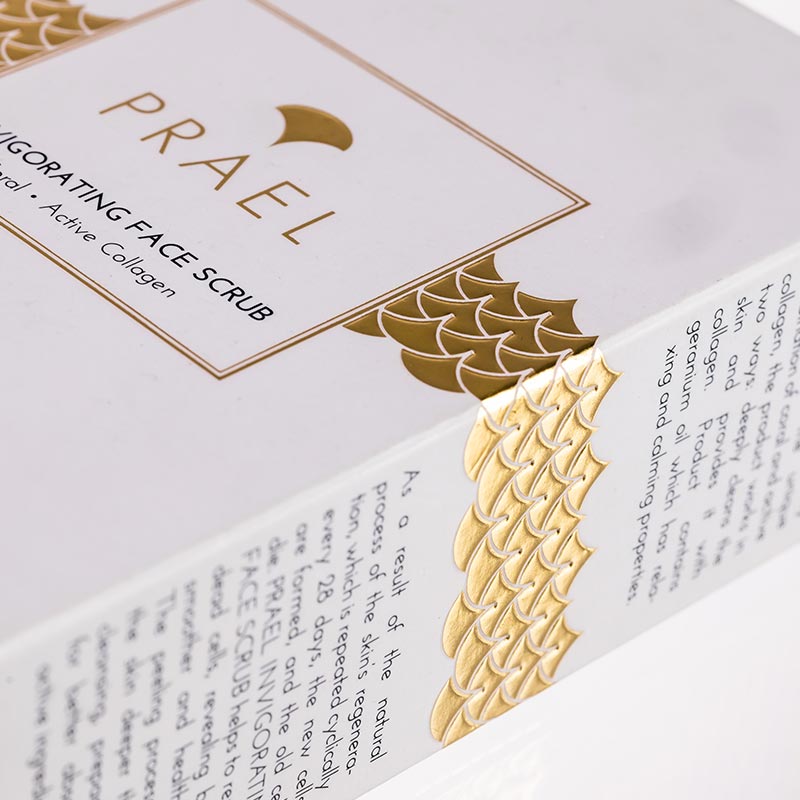

Soft touch effect•

Soft touch is a packaging finish that makes the surface feel silky and velvety. This technology can be applied on almost any printed product.

Soft touch can be made in several ways, including PET lamination and coating. The soft touch film is applied onto the entire surface of a sheet. It makes it possible to apply further finishing such as UV varnish or hot stamping. A velvety effect can also be achieved by printing special types of soft touch varnish – both conventional and UV.

Hybrid effect•

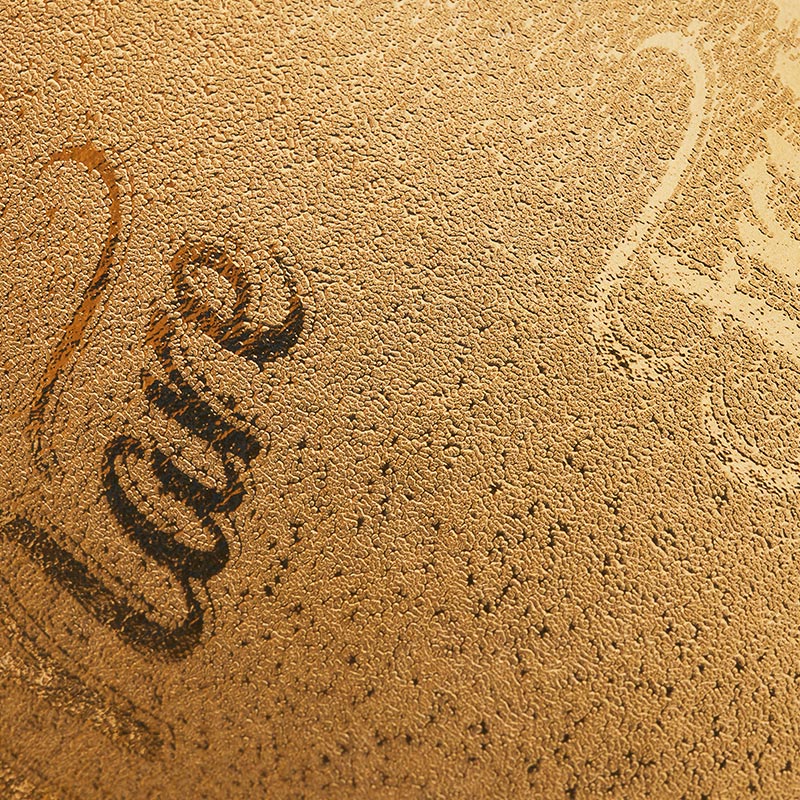

The hybrid effect, also known as “drip off”, is achieved by simultaneously applying two visually different varnish types that result in a spot gloss and matte overlay. In the areas where the matte effect is obtained, the structure of the varnish creates an effect of roughness, which can be fine or coarse (the so-called “orange peel”).

The hybrid effect is also achieved by using a combination of coating with different drying technologies, or by using special varnish.

Embossing•

Embossing is a process of creating patterns on cardboard with a 2D or 3D effect.

Special tools are used to create a high relief, debossing or a 3D effect, Braille text embossing, or the so-called dry embossing, with a delicate effect.

Embossing is usually combined with other finishing methods, e.g. hot stamping or spot coating with special or UV varnish.

Contact us•

Tell us about your project and we will come back to you with a proposal for implementation.

Address

DOT2DOT SA

Headquarters

7R PARK GDAŃSK II, ul. Magnacka 35

80-180 Kowale, Poland

![]()

Call us on the number Tel: +48 (58) 346 9188

![]()